The Benefits of Molded FRP Grating:

High Loaded Strength

Our continuous fiberglass strand alternating layers and one-piece construction distributes loads to bi-directional bars for greater tensile strength.

Impact Resistant

Unlike metallic grating, which will deform and need replacement, our molded fiberglass grating allows for repeated deflections without any permanent damage.

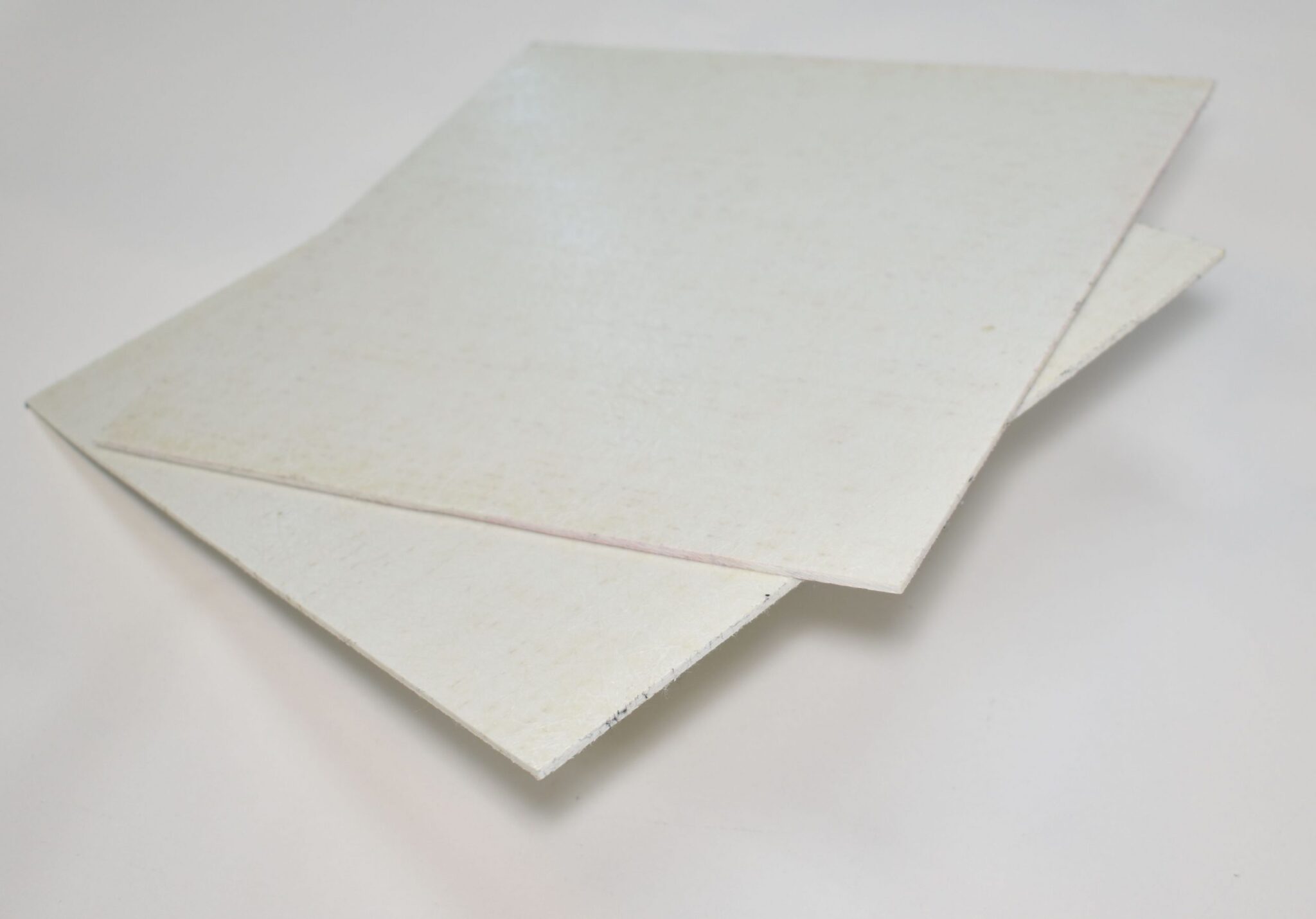

Anti-Corrosion, Attractive, & Low Maintenance

Inherent properties in our molded grating, like corrosion/rust resistance from high resin content, and molded-in color and UV resistance means freedom from painting and/or coating, as well as a longer lifespan for your applications.

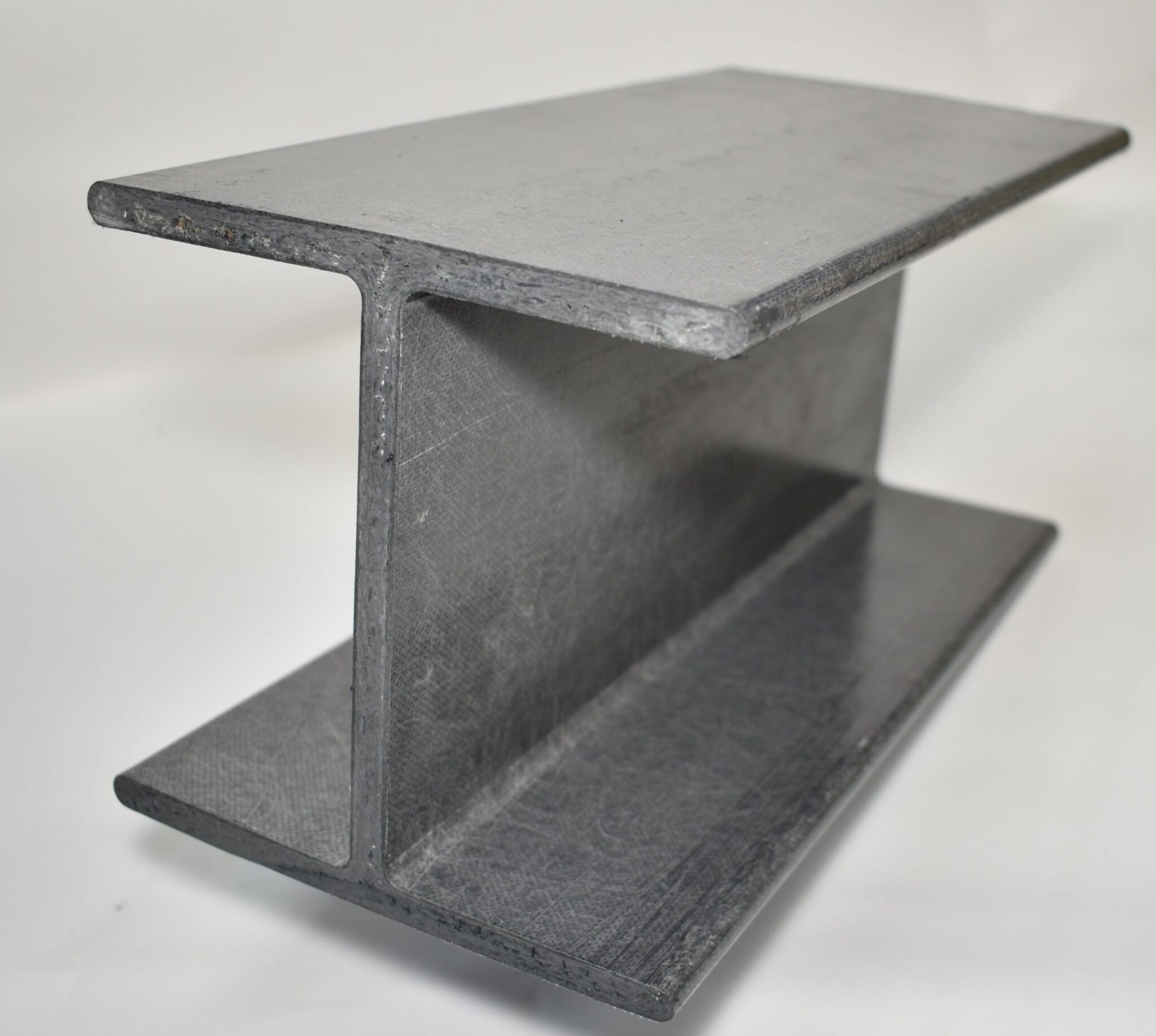

Lightweight & Easy to Install

At about one-fourth the weight of steel, a full panel of our molded grating can easily be lifted and moved by two people, as well as readily cut to fit your applications using a commercial saw instead of industrial-grade equipment.

Non-Conductive & Non-Sparking

Perfectly suited for electrically hazardous locations or conditions, our molded grating has inherent insulating properties that reduce the risk of electrical shock. It is also well-suited for many applications where sparks can trigger explosion or fire due to combustible gases build-up.

Anti-Fire

All of our resin systems have a Class 1 flame spread rating of 25 or less per ASTM E84.

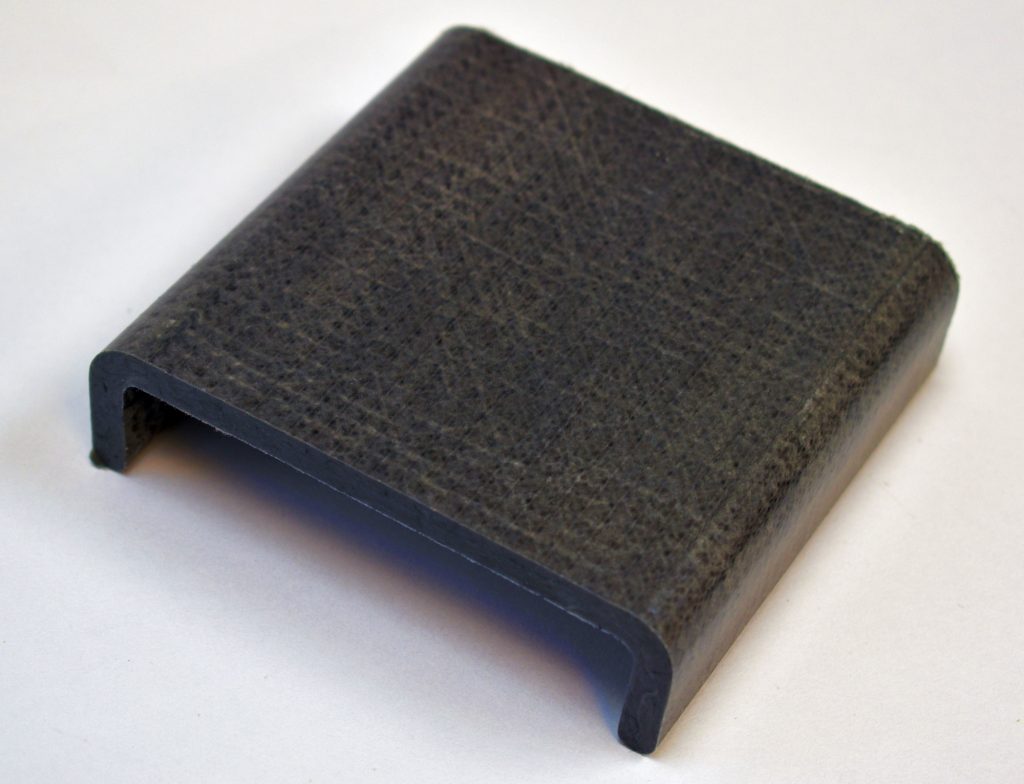

Anti-Slip Surface

With multiple surfacing options, our molded grating can offer maximum slip resistance designed specifically for your application. The built-in concave surface offers protection, while the gritted surfaces provide superior protection for less wear and tear.

Chemical & UV Resistant

Our molded grating process ensures excellent resistance over a wide PH range – both acidic and caustic, as well as protection from ultraviolet rays.